Silicone adhesives like DOWSIL 3140 and 3145 RTV might not be the first thing that comes to mind when you think about advanced technology, but they play a crucial role.

These adhesives are essential in various industries, offering reliable performance for complex applications. Let’s examine how DOWSIL 3140 and 3145 RTV significantly impact this field.

What is DOWSIL 3140?

DOWSIL 3140 is a room-temperature vulcanizing (RTV) silicone adhesive known for its clear, non-flowing, and versatile properties. It is predominantly utilized in the electronics industry and excels in coating, potting, and encapsulation applications.

What sets DOWSIL 3140 apart is its ability to adhere to a diverse range of substrates, including challenging materials like metals, plastics, and ceramics.

Its composition provides a unique flexibility and thermal stability blend, maintaining performance across a broad temperature spectrum.

DOWSIL 3140 employs a moisture cure system, which enables it to cure at ambient temperatures upon exposure to air moisture, offering convenience and efficiency in various manufacturing and repair processes.

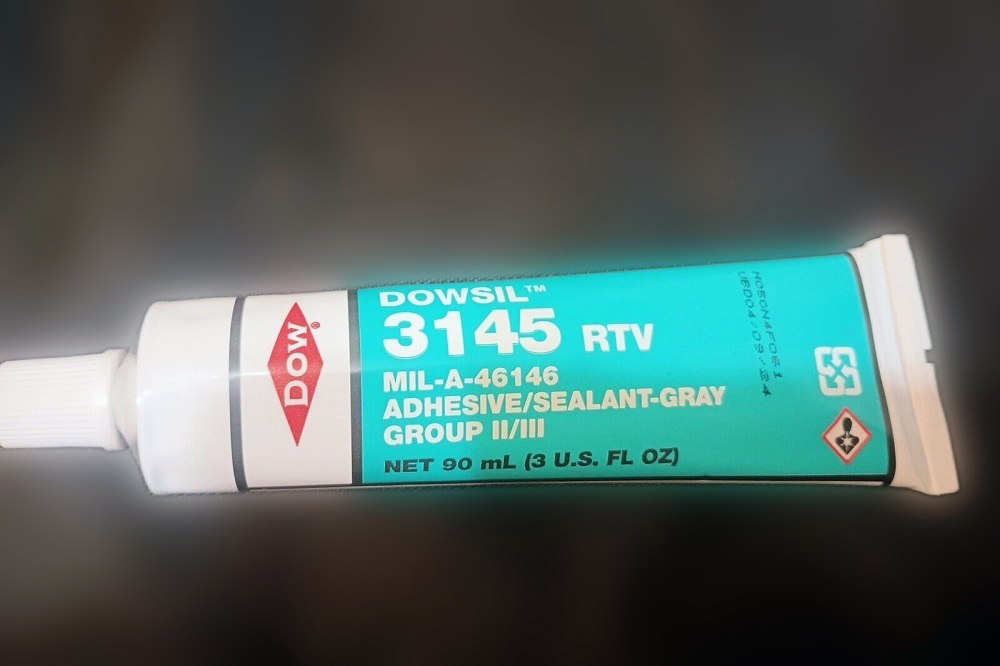

What is DOWSIL 3145 RTV?

DOWSIL 3145 RTV is a robust, high-strength adhesive/sealant designed for demanding bonding and sealing applications. It’s particularly favored in the automotive and aerospace industries for its ability to withstand extreme environmental conditions.

DOWSIL 3145 showcases exceptional resistance to temperature fluctuations, ozone, and UV light, making it a prime choice for outdoor and high-stress applications.

Its thixotropic, non-sagging nature allows for precise application on vertical or overhead surfaces, a critical feature for complex assembly tasks.

How are they different?

• Viscosity: DOWSIL 3140’s lower viscosity is optimal for smooth coating and potting, while DOWSIL 3145’s thicker consistency aids in bonding and sealing, preventing drips and runs on vertical surfaces.

• Strength and Durability: DOWSIL 3145 offers enhanced tensile and shear strength, crucial for structural applications demanding robust mechanical properties.

• Cure Mechanism: DOWSIL 3140 cures through a moisture cure system, convenient for environments with varying humidity levels. DOWSIL 3145, with its unique curing process, results in a more rigid bond.

• Primary Uses: DOWSIL 3140 is preferred for protective coatings and electronic encapsulation, while DOWSIL 3145 is tailored for structural bonding and sealing, especially in high-stress environments.

• Heat Resistance: Both adhesives perform admirably under thermal stress, but DOWSIL 3145’s formulation provides superior performance at elevated temperatures.

How are they similar?

• Silicone Base: Both products are silicone-based, offering excellent resistance to chemicals and retaining flexibility over time.

• Room-Temperature Curing: As RTV adhesives, they cure at room temperature, eliminating the need for additional heating equipment.

• Adhesive Qualities: Each adhesive forms strong bonds with various materials, including metals, glass, and ceramics, showcasing their adaptability.

• Operating Temperature Range: Both adhesives maintain their properties at various temperatures, making them suitable for extreme applications.

• Environmental Resistance: Their resistance to weathering, ozone, and UV light makes them ideal for long-term outdoor applications.

What’s better about DOWSIL 3140?

• Flexibility and Expansion: DOWSIL 3140 remains flexible, accommodating material expansion and contraction, essential in fluctuating thermal environments.

• Application Ease: Its lower viscosity ensures effortless application, spreading evenly for coatings and potting.

• Optical Clarity: The clear nature of DOWSIL 3140 is advantageous in applications where visual aesthetics are important.

• Moisture Protection: It offers superior moisture resistance, protecting electronic components from humidity and water damage.

• Application Range: DOWSIL 3140’s physical characteristics make it versatile for various applications, from simple coatings to intricate electronic encapsulations.

What’s better about DOWSIL 3145 RTV?

• Enhanced Mechanical Strength: DOWSIL 3145 is engineered for applications where high tensile and shear strength are paramount.

• Superior Heat Resistance: Its formulation withstands higher temperatures, which is ideal for applications in harsh thermal environments.

• Non-Sagging Property: The adhesive’s thixotropic nature prevents sagging, facilitating application on vertical or overhead surfaces.

• Durability: DOWSIL 3145’s robust composition ensures longevity, especially in demanding industrial applications.

• Targeted Applications: Its specific properties make it more suitable for structural bonding in automotive, aerospace, and construction industries.

Who should get DOWSIL 3140 (and why)?

DOWSIL 3140 is particularly suitable for electronics professionals engaged in potting and encapsulation. Its electrical insulation capabilities, moisture resistance, and optical clarity make it indispensable for safeguarding sensitive electronic components.

Hobbyists and DIY enthusiasts will also find DOWSIL 3140 beneficial for various home projects, thanks to its ease of use and adaptability to multiple surfaces and environments.

Who should get DOWSIL 3145 RTV (and why)?

Professionals in the automotive and aerospace industries will find DOWSIL 3145 RTV highly beneficial for its strength and resilience in extreme conditions. Its suitability for structural bonding and sealing makes it essential in manufacturing and maintenance.

Additionally, architects and construction professionals working on outdoor or high-stress projects will appreciate its durability and resistance to environmental factors.